TPE rubbing towel material shake sonic boom

Contact 138 2720 9711

Product details

Recently, the tremulous TPE washcloth materials have revolted the entire TPE industry, which is as hot as PP meltblown materials. So today Dechuang Chemical Company will explain that TPE and silica gel materials are more suitable for washcloth. What's the difference between TPE raw materials and silicone rub towels?

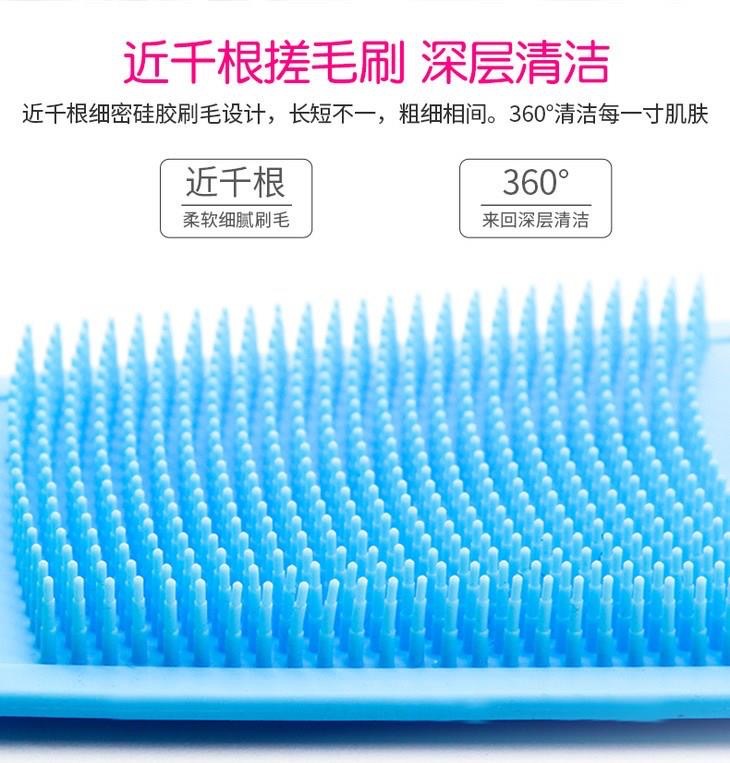

Silicone scrub is designed to be strip-shaped, healthy and environment-friendly. It does not contain harmful substances such as bisphenol A, and is resistant to high and low temperatures and is not easy to crack. Silicone scrub, double-sided silicone brush; Soft and comfortable, gentle without hurting skin; Soft and elastic. Good quality makes a good life. Handle design comfortable hands easily rub back, rub out milk-like beauty back. Hanging hole design is convenient for storage. The back of the anti-fatigue brush is designed with an oval shape, and the back of your personal masseuse bulges to relieve your fatigue. Thousands of silicone bristles are cleaned layer by layer, leaving no room for dirt to go 360 degrees back and forth for deep cleaning, rubbing back and massaging Dont Ask For Help. Silicone bath brush rub bath good helper. Double-sided function Two-way selection of bristle surface bubble bath, hemisphere massage, bath is simpler.

TPE scrub belongs to imitation silicone products. TPE is called thermoplastic elastomer. It is a high molecular polymer or high molecular alloy material with the structure of soft rubber segment (or rubber phase) and hard plastic segment (or continuous plastic phase). The most common TPE refers to blending SEBS and SBS.

Silicone has excellent rebound resilience and small permanent deformation, and TPE material has worse performance in this aspect. TPE and silica gel are both environment-friendly and nontoxic, but for the test of food contact materials, silica gel meets FDA21CFR177.2600 and EU LFGB olive oil test standards, while TPE basically fails to pass these two test standards.

TPE material has smooth and soft hand feeling, hardness in the range of 0A-120A, simple processing and molding, no need of vulcanization processing, recycling, and cost reduction. It can be coated and bonded with PP, PE, PC, PS, ABS and other plastic materials (secondary injection molding) or can be formed separately.

TPE material is different from silica gel. Judging from the above knowledge points, TPE material can replace silica gel to produce washcloths. It also has the properties of environmental protection, softness and good rebound resilience, but if some customers require the washcloth to pass the food grade, it is not recommended to use TPE material for production with silica gel. TPE materials are used for those with low requirements, and the overall cost will be much cheaper. For more information about TPE raw materials, please pay attention to us!