Case handle TPE ADHESIVE PP webbing material

Contact 138 2720 9711

Product details

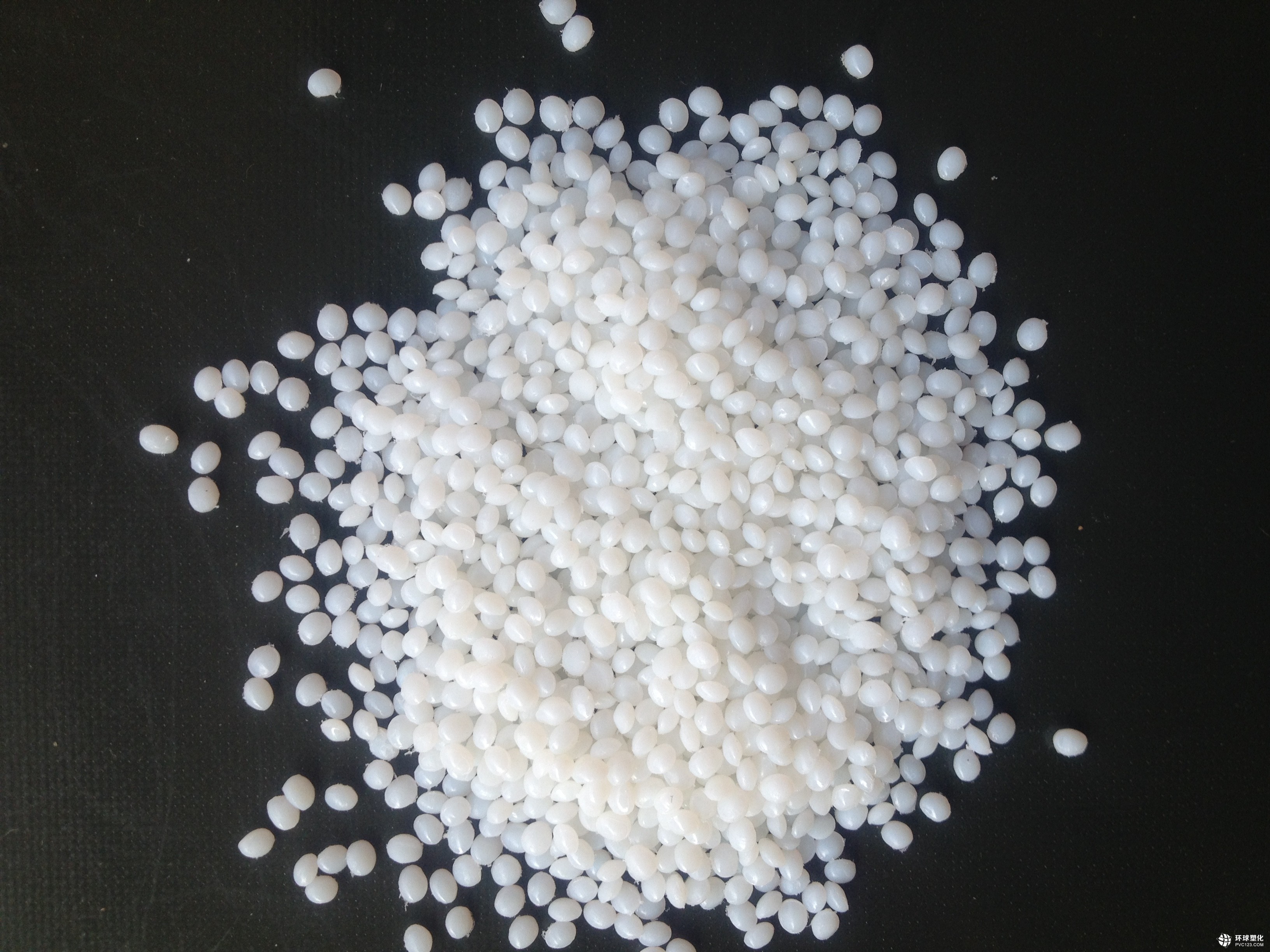

TPE PLASTIC MOLDING PROCESS: TPE Elastic plastic can be injection molding, extrusion, blow molding, salivation, pouring and other ways to processing molding. TPE is a material with high elasticity, high strength, high resilience of rubber and the characteristics of plastic injection processing. TPE and TPR differences: TPE plastic can also be called TPR, TPE and TPR confusion, TPE is based on SEBS as a material blending modified materials, SBS modified materials called TPR. In Hong Kong, Taiwan most like to call TPR, in the mainland most like to call TPE, in fact, TPE, TPR is just Thermoplastic elastomer material of different call. It has the characteristics of high elasticity of rubber and plastic injection processing. The utility model can be reused effectively to save energy, and is an ideal material to replace rubber and Silica Gel. TPE plastic application in the field of plastic packaging: TPE Elastic plastic used in the secondary injection plastic packaging, TPE plastic as a soft plastic coating, common co-hard material is mainly plastic, but also metal and cloth. TPE and weaving shot stick is mainly used in luggage products, with the same as the metal coating, are generally fake coating. True package plastic is more common in secondary injection molding and two-color injection molding, that is, TPE package adhesive is the main material is plastic. TPE can be used with some common plastics PP, GPPS, HIPS, ABS and Engineering Plastics PC, PC / ABS, PA and its modified materials bond firmly.TPE PLASTIC MOLDING PROCESS: TPE Elastic plastic can be injection molding, extrusion, blow molding, salivation, pouring and other ways to processing molding. TPE is a material with high elasticity, high strength, high resilience of rubber and the characteristics of plastic injection processing. TPE and TPR differences: TPE plastic can also be called TPR, TPE and TPR confusion, TPE is based on SEBS as a material blending modified materials, SBS modified materials called TPR. In Hong Kong, Taiwan most like to call TPR, in the mainland most like to call TPE, in fact, TPE, TPR is just Thermoplastic elastomer material of different call. It has the characteristics of high elasticity of rubber and plastic injection processing. The utility model can be reused effectively to save energy, and is an ideal material to replace rubber and Silica Gel. TPE plastic application in the field of plastic packaging: TPE Elastic plastic used in the secondary injection plastic packaging, TPE plastic as a soft plastic coating, common co-hard material is mainly plastic, but also metal and cloth. TPE and weaving shot stick is mainly used in luggage products, with the same as the metal coating, are generally fake coating. True package plastic is more common in secondary injection molding and two-color injection molding, that is, TPE package adhesive is the main material is plastic. TPE can be used with some common plastics PP, GPPS, HIPS, ABS and Engineering Plastics PC, PC / ABS, PA and its modified materials bond firmly.